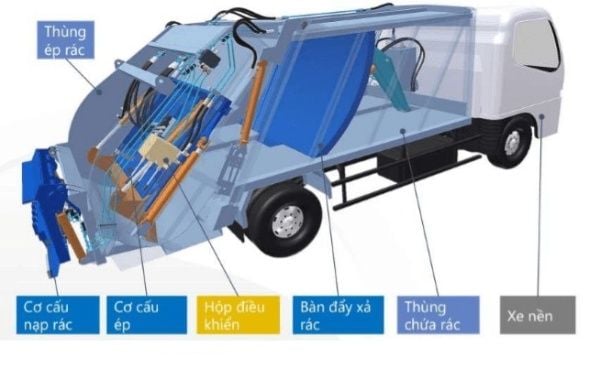

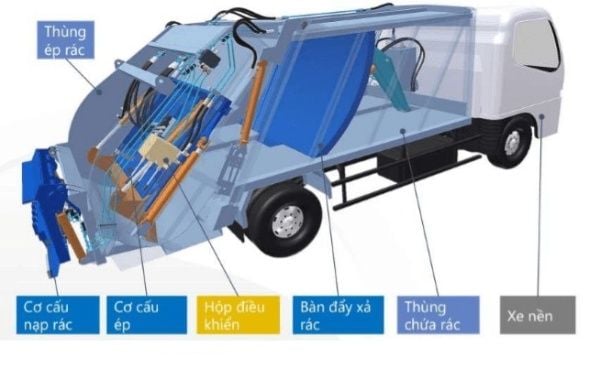

GARBAGE COMPANY TRUCK is a specialized vehicle used to collect and transport municipal waste or other types of compactable waste. The vehicle has a crushing and compacting mechanism, with a high compression ratio and large carrying capacity. There is a closed waste collection and transportation process, ensuring hygiene and avoiding environmental pollution.

1. The vehicle structure includes the following parts

- Vehicle chassis

- Power system

- Hydraulic compression system (including: hydraulic cylinders, pumping equipment, pressure regulating valves, electro-hydraulic control valves and pipes).

- Waste container (equipped with push tray, moves along slider)

- Loader tank (including compression plate, excavator plate, compression cylinder, excavator cylinder and lifting cylinder)

- Safety equipment (including safety bar, horn, brake valve, automatic shut-off switch, pressure release valve, etc.)

2. Operating principle

First, the waste will be put into the loading bucket (if equipped with a waste scooper or waste shovel. First turn the handle of the scooper to scoop the waste, then put it back in the central position).

- Turn the feed switch clockwise, then the compression plate will flip and the loader plate will be lifted. Finish the first compression process.

- Turn the loading switch counterclockwise, then the compactor tray will rotate, the excavator tray will lift up, and the waste will be crushed in the cavity between the pusher tray, the fixed tray of the loading bucket and the compaction tray. Thus, one operating cycle has been completed, turn the switch to the center position to turn off.

- When pushing waste, pressure will be created, so the waste will be compressed again.

- After the container is full, transport the waste to the landfill, then lift the loading bucket to discharge the waste.

3. Use and operation

Usage includes how to drive the vehicle and operate specialized functions.

a. How to drive

- Strictly follow the instructions for use.

- Before driving, ensure that the intake door is lowered, locked and the PTO is turned off. Otherwise, it may cause a pump fire.

b. Operate specialized functions

- Drivers and operators need to work closely and harmoniously.

* Prepare

- Leave the number “0”. PTO switch is in the “off” position, hand holding the brake.

- Foot rest on clutch pedal.

- Start the machine.

- Engage the PTO, the indicator light turns on.

-Release the clutch (the drive pump starts running)

-Make sure the hinge lock is in the locked position. Otherwise it will be very dangerous.

Note: 1. If the engine is cold in winter, warm it up before starting.

* Operate the feeding mechanism

- Open and push the loading door up until you hear a “kada” sound to make sure the loading door is fixed in the open position.

- Operators need to work together to ensure that the hinge lock is inserted into the lock pin.

Note: After the garbage is full and during compaction, if the lock is not fully locked, the impact may cause the loading bucket to open.

Note: Garbage needs to be evenly distributed in the bin.

* Waste in the container will be compressed and crushed in the following order:

- The compressor tray flips up.

- After the compression tray stops, the loader slides down to the position of the feeding mouth, and the loader stops.

- When the loader stops, the compactor begins to rotate, compressing the waste from the feed mouth into the middle of the container.

c. When the compactor stops, the loader begins to turn over, the waste is crushed inside the compartment, and is pushed into the container.

Note: To load the waste smoothly, the waste must be loaded many times, a little each time.

d. Waste disposal

- Press the accelerator switch (at the rear of the car)

- Place the operating handle at the waste container lifting position.

- Unlock and the waste container is raised.

- When the waste container is completely raised, turn the push tray switch to the “PUSH” position. The push tray will slowly push the waste backwards.

- After the discharge process is finished, reset the push tray to the same position as before, then turn the operation switch of the container in the cabin to the "DOWN" position, the container will begin to lower.

* After lowering, pull the hydraulic valve locking device hook handle, making sure the hook is hung up.

Note:

(1) To make it easier for the pusher to clean waste, the front and bottom of the pusher is 50 mm longer than the back. Be sure to clean off any debris that may remain between the ejector plate and the rear of the tank, otherwise damage to the lower front of the ejector plate may result when the ejector plate returns to its original position.

(2) Make sure the garbage between the container and the bucket is cleared, otherwise the auto-lock will not work.

e. Final stage

- Place your foot on the clutch pedal (depress the clutch)

- Disconnect PTO

- Turn off the engine and release the clutch.

- Close the loading door of the loading bucket.

- Safety principles and attention

e. Prepare before operating

Preparation and inspection should not only be based on the requirements in the vehicle inspection manual but also check the following items:

- The hydraulic oil level in the tank is still within the allowable limit.

- Check the connections and parts of the hydraulic system to see if they are cracked or broken.

- P.T.O must always be in the best conditions.

- All buttons, switches and manual controls must be in good condition.

- All operating parts must be in good condition and connections must be tight.

f. During operation

Preparation and inspection should not only be based on the requirements in the vehicle inspection manual but also check the following items:

- The operating process must strictly comply with the rules, drivers and workers must always be in contact with each other.

- While lifting the trash, do not put your feet or body inside the trash bucket.

- It is unavoidable that trash gets stuck at the top of the hopper or when checking and maintaining the hopper. In that case, it is necessary to pull down the safety latch (Safe Stick) and the hopper needs to be brought down a bit for it to hang. on the Safe Stick to ensure it will not be pushed out and affect the vehicle. When bringing down, you need to stand to the right.

- While raising or lowering the funnel, make sure there are no people or objects around and do not move the vehicle.

- Before raising the hopper, make sure there is no waste inside.

- After storing trash, while driving, make sure there is no more trash in the hopper.

- When one of the following operations (raising, lowering, pushing and discharging) is completed, loosen the control handle, do not press for a long time.

- While loading, force the waste deep into the hopper, making sure there is no waste stuck at the entrance and the waste does not fly around. Do not stay in the hopper or put your feet on the hopper during the trash compacting process.

- Garbage must be distributed symmetrically and must not be too much compared to capacity. Do not allow waste containing reinforced concrete, machinery such as iron blocks and other incompressible waste (e.g. sewing machines, motors, etc.)

- During transportation, automatic gun devices can accelerate the speed of the engine. Therefore, do not step on the accelerator, otherwise it will damage the pump and PTO.

- When the vehicle is full of garbage, the overflow valve will work, so you must stop loading garbage into the vehicle at this time. Do not overload.

- While compacting the trash, the push tray is broken. Stop compacting the trash immediately and do not operate it until it is repaired.

- Please keep the height of the hopper while lifting to avoid causing damage to the vehicle and other vehicles, make sure that there is no one or anything between and around the person and the hopper.

- Do not carry dangerous substances.

g. After operation

Not only check the problems listed in the vehicle owner's manual, but also check the following items:

- See if there are any dangers affecting the vehicle's operating parts.

- Waste inside the container and in the hopper and behind the push tray must be cleaned.

- Check to make sure there is no trash in the trash container.

H. Use safety latch during lifting the hopper

- Because the hopper can only be opened for cleaning, inspection or repair, it is necessary to use a safety latch to avoid danger. To ensure safety during inspection and repair, do not stand under the funnel.

- Use the safety latch: After pressing the safety latch, make sure the latch can rotate. When using both sides of the pin must be placed down at the same time. Keep a distance of about 2-10 cm between the front of the dowel and the funnel. Please do not place the funnel directly on the safety pin, to avoid exposing the safety pin to too much force.

i. When the engine is working, for safety reasons, no one must go between the vehicle and the hopper. In case of cleaning, inspection or repair, stop the engine, take out the key and keep the key when enter.

4. Maintenance

* Please clean your car seriously.

After each working day, if waste is left stuck to the corners of the cart and hopper, it will rot. Vehicle cleaning needs to be carried out seriously from beginning to end, especially in the recesses, corners, edges, etc., ensuring there is no waste or sand in the sealed surface between the vehicle and the hopper, otherwise it will damages the seal and causes waste to seep out.

* Adjust the locking part

The locking part is fixed to the body of the vehicle and it plays a very important role. You must check the key holes to see if the hooks are firmly attached to the lock sockets, and to see if they are warped or worn. .

* Change hydraulic oil every 6 months, in summer, use oil with symbol YB-N46, in winter use oil with symbol YB-N32. Must ensure the correct type of oil or not less than 30 µm.

Note: Must use the same type of hydraulic oil, do not mix.

* Replace the high pressure rubber once a year or if it is found to be damaged.

* Lubricant

Every week, use the right type of lubricant in the right place.

5. Replace the device.

Each replacement must ensure safety and must be periodic and the vehicle user can do it themselves, thus reducing costs.